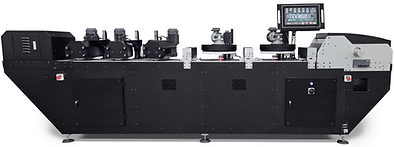

Flooring finishing line for oil, lacquer, and UV coating processes.

Flooring Finishing Line for Wood Flooring Production

The Flooring Finishing Line is an industrial machine designed for controlled application, post-application surface treatment, and curing of finishing agents on wood flooring surfaces, including parquet and engineered flooring products.

The finishing line is built around a digitally coordinated, self-configuring process architecture designed to minimize manual tuning and stabilize finishing results across different production scenarios.

Within the Deck Art Machines finishing technology portfolio, the Flooring Finishing Line serves as the core finishing platform and reference unit for standalone production lines and expanded multi-step finishing systems.

Function of the Flooring Finishing Line

The Flooring Finishing Line performs the core finishing operations required to transform a prepared wood flooring surface into a finished product. These operations are executed in a defined sequence within a continuous production flow.

The finishing process begins with controlled application of the selected finishing agent onto the flooring surface using roll coating. Immediately after application, the surface passes through treatment units that distribute and even the applied material.

The final stage of the process is curing of the applied finish, performed using the selected curing technology. Once cured, the flooring exits the line as a finished surface, ready for handling, stacking, or transfer to subsequent production stages.

Continuous finishing process combining application, post-application surface treatment, and curing within a single production line.

Integrated Process Units

Roll coater module for controlled finish application.

Roll Coating Unit

Applies finishing agents to the flooring surface in a controlled and repeatable manner. Supports oils, lacquers, and UV-curable coatings across defined working widths and thickness ranges.

Post-application surface treatment using pads and brushes.

Buffing and Wiping Units

Performs post-application treatment of the applied finish to distribute material, control surface texture, and remove excess coating. Units operate in sequence based on the selected finishing process.

Curing module configured for the selected coating system.

Curing Unit

Cures the applied finish using the selected curing technology. The line can be configured with LED UV, classic UV lamp, or hybrid curing systems depending on coating type and production requirements

Visual overview of integrated finishing process

These short clips show the finishing line layout and a complete processing pass from board loading through coating, surface treatment, and UV curing.

Walkaround view of the Flooring Finishing Line and integrated process units.

Board processed through roll coating, buffing/wiping, and UV curing in one pass.

Operating Parameters and Compatible Materials

The Flooring Finishing Line is designed to process a defined range of flooring dimensions and finishing materials. Operating parameters are configured digitally to support consistent processing across different production scenarios.

Working Ranges

-

Flooring width and thickness configurable within defined machine limits

-

Adjustable feeding speed to match coating type and process requirements

-

Digitally controlled working parameters for repeatable operation

Compatible Finishing Materials

-

Hardwax oils and natural oils

-

UV and LED UV oils

-

UV lacquers and varnishes

-

Water-based lacquers and stains

Digital configuration of operating parameters via the central control interface.

Position in a Flooring Production Line

The Flooring Finishing Line is designed to operate as a defined process stage within a complete wood flooring production line. Its role is to perform finishing operations on flooring surfaces that have already been dimensioned and prepared upstream.

Prior to finishing, flooring typically undergoes surface preparation and pretreatment processes such as sanding, brushing, or surface conditioning. These operations are performed by upstream equipment and are not part of the Flooring Finishing Line itself.

After exiting the finishing line, finished flooring can be handled, stacked, or transferred to downstream processes such as intermediate drying, inspection, or further production steps depending on the overall line configuration.

Flooring pretreatment unit positioned upstream of the flooring finishing line in a production system.

Inline integration of pretreatment and finishing systems

These clips show the pretreatment unit and finishing line operating as a single inline system, from surface preparation through finishing and final surface result.

Walkaround view of the pretreatment unit integrated inline with the finishing line.

Deep wire brushing pretreatment followed by finishing, with close-up view of the processed surface.

Line Layouts and Scaling Concepts

Production capacity and finishing complexity are increased by combining multiple finishing stages into structured line layouts. Scaling is achieved by repeating core finishing units and connecting them through material handling systems.

A single Flooring Finishing Line represents one complete finishing stage. Multi-step finishing processes are created by adding additional finishing lines in sequence, allowing multiple layers of coating and curing to be completed within a single production flow.

Depending on available space and workflow requirements, finishing lines can be arranged in straight in-line layouts or in compact U-shaped configurations. Material transfer between stages is handled by motorized conveyors or cross-transfer systems.

Example layout showing multiple finishing stages connected into a structured production line.

Finishing Results and Surface Examples

The following examples illustrate a range of wood flooring surface finishes produced using the Flooring Finishing Line. Examples are shown for reference and demonstrate different coating types, textures, and visual effects.

Examples of wood flooring surface finishes and textures produced using different finishing configurations.

Control Interface and Operation

The Flooring Finishing Line is operated through a centralized digital control interface that manages process parameters and unit coordination. The interface is designed for clear process overview and repeatable operation.

Operating parameters such as feeding speed, application settings, and unit activation are set through the touchscreen interface. Parameter sets can be saved and recalled to support consistent processing across different finishing scenarios.

During operation, the control system coordinates the individual process units to maintain stable workflow conditions. Operator interaction is limited to monitoring, adjustments when required, and routine production tasks.

Centralized touchscreen interface for configuring and monitoring finishing processes.

Digital setup and coordinated process control

These clips demonstrate how process parameters are defined through the control interface and how the system automatically reconfigures both finishing and pretreatment units.

Entering board dimensions and coating parameters, followed by automatic system configuration and start.

Manual adjustment of application quantity and surface state, with automatic reconfiguration of finishing and pretreatment units.

Digital Process Control and Finishing Architecture

Conventional flooring finishing lines are based on independently adjusted process units that require manual tuning and corrective steps to achieve stable results. The Flooring Finishing Line is designed around a digitally coordinated finishing architecture that treats application, surface treatment, and curing as one controlled process.

Finish application is defined digitally by setting the target application quantity directly. Based on these inputs, the roll coating unit configures itself automatically, reducing the need for manual mechanical adjustment typical of conventional finishing lines.

Application parameters are not limited to the coating unit alone. Process settings are coordinated across post-application treatment units and curing stages, allowing buffers, wiping brushes, and curing systems to adapt consistently to the selected finishing scenario.

As a result of precise application control and coordinated downstream processing, corrective techniques such as reverse roll application become optional rather than mandatory. This simplifies configuration and supports repeatable results across different finishing recipes.

System-level finishing architecture coordinating application, surface treatment, and curing stages.

A detailed technical explanation of the self-configuring finishing architecture is provided separately.